Email:[email protected]

Email:[email protected]

Eco-friendly bio-based nylon is getting more reflection due to its less harmful impact on the Earth than regular nylon. Traditional nylon is produced from oil, which can be harmful to the environment. But bio-based nylon comes from plants, which can be farmed repeatedly.

Bio-based nylon is made using natural resources such as corn, soybeans or sugarcane, rather than oil. These are all planted on Farm as well and can be planted year after year so these are a good source for a nylon make.

This not only provides a sustainable source of nylon, but also results in fewer carbon emissions, harmful gases released during the process of making nylon from shale gas. Opting for bio-based nylon vs. nylon helps keep the Earth safe for generation to come.

You are not taking away new resources from our land and biosystemAnother point in favor of bio-based nylon is the lower environmental footprint it represents. Producing conventional nylon can consume large amounts of water and energy, contributing to pollution and climate change.

A lot of companies currently product bio-based nylon products because they wish to do better by the atmosphere. By using bio-based nylon, these companies can reduce their carbon footprint and illustrate their concern for the Earth.

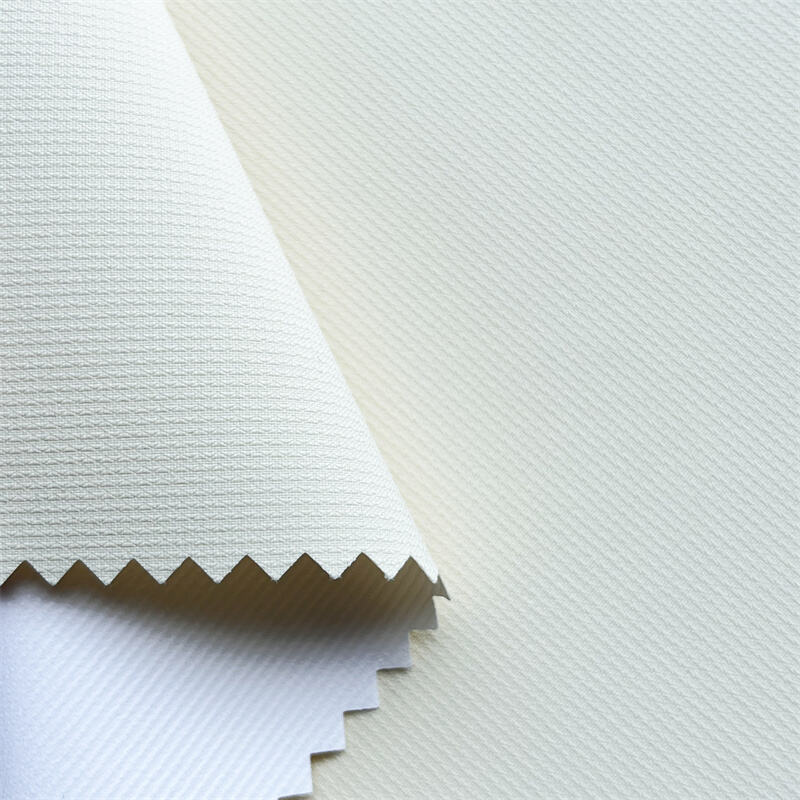

In addition, bio-based nylon is flexible enough to be used in a large range of products, from clothes to car parts. Companies who choose bio-based nylon produce high performance products that are more sustainable for the planet.

Overall, bio-based nylon is a major step in the right direction, promoting the creation of a more sustainable world for us all. The bio-based nylon fibers help create a cleaner planet by utilising natural resources, whilst minimising the impact of conventional nylon.

Sunfeng Fabric binds skin the Earth by creating an eco-system is transparent and low carbon. is biodegradable and recyclable. is virtually zero bio based nylonrecycling 95% waste.

2022, the business created Sichuan Sunfeng Digital Intelligent Textile Co., Ltd which combines textiles, dyeing and finish. In addition Vietnam base is equipped with a weaving and dyeing facilities as well as bio based nylonfacility. weaving facility began operation in 2021 and has a production capacity approximately 40 million meters annually.

company is certified by GRS, Bluesign, Okeo-tex 100, Okeotex step Higg Index as well as BSCI. Additionally, it has rigorous quality control. From initial testing of samples to dyeing finishing, entire process is tracked and bio based nylon. ERP intelligent system is able to save all order information in real-time, and it is completely transparent.

Sunfeng founded 2005 is a high-tech business focuses on R D and the production breathable and sustainable functional fabrics. The company has the latest R D labs and CNAS test laboratories, and collaborates with universities and scientists to improve technology final production for bio based nylonscenarios market needs.