Email:[email protected]

Email:[email protected]

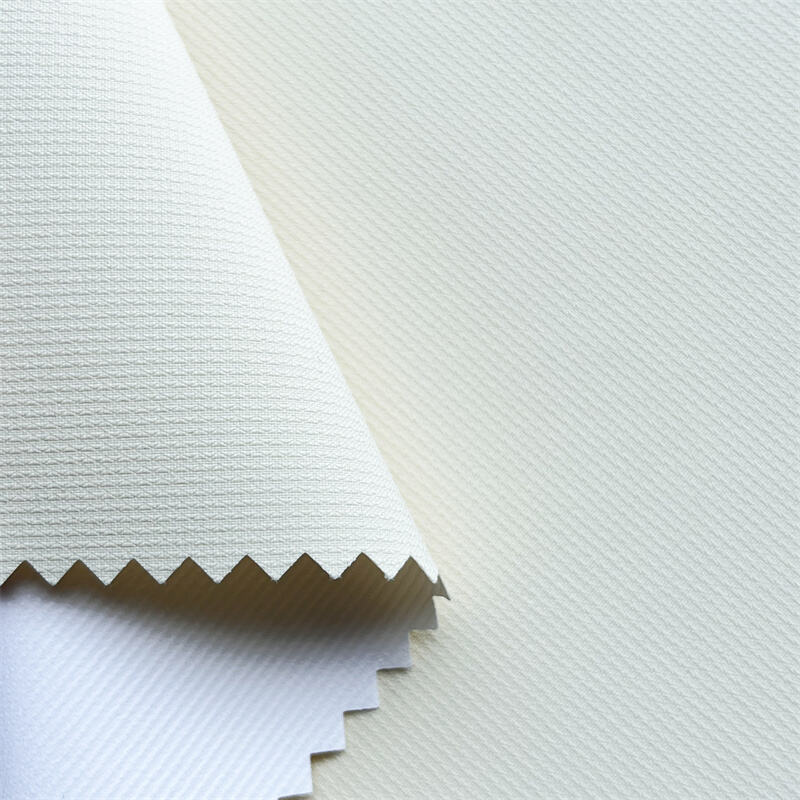

The carbon fiber filament is a type of filament that is lightweight and very strong. It consists of bunches of tiny bits called carbon fibers which are twisted together into one long thin thread. This incredible material has a ton of awesome benefits and is revolutionizing the way we make things such as planes and cars. A strand of carbon fiber is made up of thousands of carbon fibers twisted together. This results in a filament that is strong and light. This filament is capable of producing a great many objects, from bicycle parts to entire rocket ships. So strong that it is often used in place of where regular materials would crack.

The heat and chemical corrosion resistance of carbon fiber filament is another advantage. That makes it a perfect raw material for car parts and industrial tools. It also has a lot of flexibility, allowing for many potential configurations without straining or fracturing. The new technology is revolutionising structures, and carbon fiber filament is no exception such as aircraft. Its strength and light weight help manufacturing airplanes that burn less fuel and reach greater heights and speeds. The lighter an airplane is, the less fuel it requires to fly.

Large filament fiber (116 to 500g/m2) is additionally used to make space rocket craft that fly to space and back. Rocket science is tough, these rockets need to be tough they need to be able to withstand the harsh conditions of space, and carbon fiber filament can provide that. Fiber filament: These are the new frontiers for us in space travel.

Another application of carbon fiber filament is in the automotive industry. Now (New York, NY): automakers are using this incredible material to make cars faster, safer, and more fuel efficient. Utilizing carbon fiber filament for components such as the body and frame, car makers can build lighter, more aerodynamic vehicles.

That means cars can travel faster and consume less fuel, which is great for the environment. Carbon fiber filament is also utilized in electric cars, which are gaining popularity since people are looking to be environmentally friendly. But the future of the car is looking very bright with carbon filament.

company is certified by GRS, Bluesign, Okeo-tex 100, Okeotex step Higg Index as well as BSCI. Additionally, it has rigorous quality control. From initial testing of samples to dyeing finishing, entire process is tracked and Carbon fiber filament. ERP intelligent system is able to save all order information in real-time, and it is completely transparent.

Connecting skin to the Earth Every meter Sunfeng Fabric boosts performance and through creation of a Carbon fiber filament, low-carbon ecosystem. Easy recyclable biodegradable production. near-zero emission production through recycling 95% of waste.

Sunfeng founded 2005 is a high-tech business focuses on R D and the production breathable and sustainable functional fabrics. The company has the latest R D labs and CNAS test laboratories, and collaborates with universities and scientists to improve technology final production for Carbon fiber filamentscenarios market needs.

In 2022, business founded Sichuan Sunfeng Digital Intelligent Textile Co., Ltd integrated textile dyeing, finishing and Carbon fiber filament. addition Vietnam base is equipped with weaving factory dyeing finishing factories. The weaving facility began operation in 2021 with annual production of 40 million meters of fabric.