Email:[email protected]

Email:[email protected]

Flexible polycaprolactone filament is a type of plastic that can be melted down and formed into a number of different applications. In this article, we will explore polycaprolactone filament more closely and see what makes it different from other 3D printing filament options.

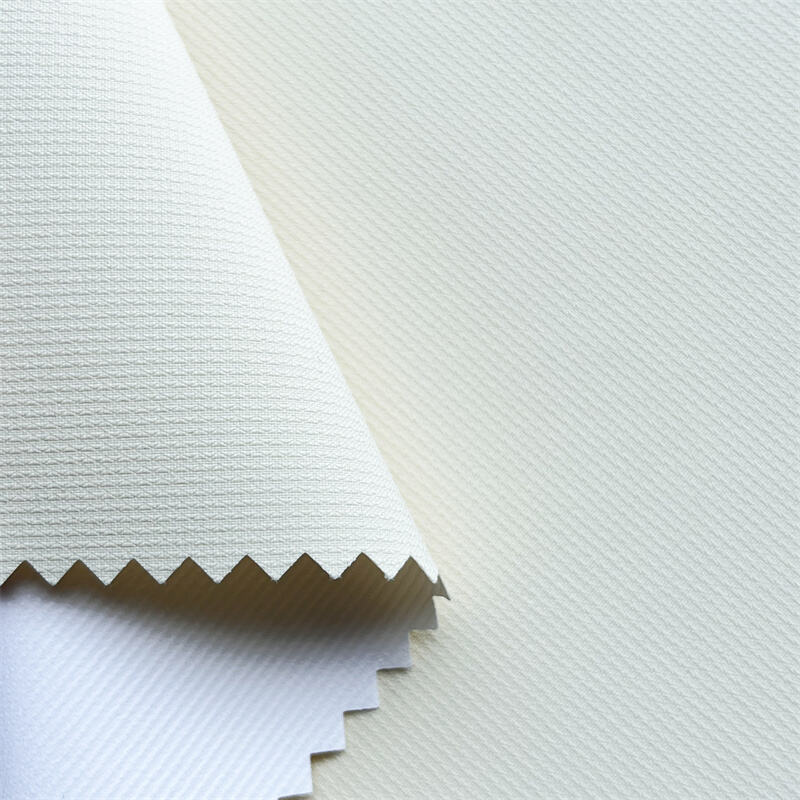

Polycaprolactone filament is constructed from small subunits called monomers. When these monomers link up, they form long chains known as polymers. This process of joining is known as polymerization. The Clear pla filament is biodegradable, so it is capable of spatial decomposition over time. So it is environmentally friendly.

The special qualities of Sunfeng polycaprolactone filament are why it is used so often. And medicine often uses it to make things like screws and plates for broken bones. The reason is that it is safe to use within the body. It is also used for 3D printing to create models and designs. The carbon fiber filament can even be found in cosmetics, glue and food packaging.

Polycaprolactone filament is a great option for 3D printing, and one big reason to use it, is that it has a low melting point. This allows it to be molded into other more elaborate designs using a 3D printer. It is also high filament strong and it flexible things for manufacturing tough. Another positive aspect of polycaprolactone filament is that it is recyclable: it can undergo several cycles of use.

Just like it is eco-friendly, Sunfeng polycaprolactone filament is also reusable multiple times. This helps cut down on waste. And because it is biodegradable, it will decompose naturally over time, leaving no toxic residue behind. This will be a good advantage for companies making products that are eco sustainable.

Since the technology surrounding polycaprolactone filament is always evolving, new and exciting ideas are appearing. Researchers are discovering improved methods for addressing the strength and utility issues of polycaprolactone filament. 3D printing regarding this good pla filament has also been simplified by new technology, yielding new design options for manufacturers. Of course, as new research and ideas come about, the potential for polycaprolactone filament will evolve even more.

2022 the Company founded Sichuan Sunfeng Digital Intelligent Textile Co., Ltd that integrated textile dyeing, finishing and weaving. Vietnam base also has weaving factories along with dyeing finishing factory. weaving Polycaprolactone filamentstarted operations in 2021, and will have a total Polycaprolactone filamentproduction capacity of 40 million meters of fabric.

Sunfeng founded in 2005 and is high-tech business that focuses R D and the production of breathable sustainable functional fabrics. The company is equipped with latest R D as well as CNAS testing labs, working with academies and scientists in order to improve the efficiency technologies and final production for Polycaprolactone filamentmarket demands.Sunfeng has received the top honors in numerous professional competitions both at home and internationally and have been awarded over 50 patents.

company accredited with GRS, Bluesign, Okeo-tex 100, Okeotex step Higg Index and BSCI. also have an Polycaprolactone filamentstrict quality control. Everything from the testing samples and dyeing through to finishing is controlled and analyzed. The ERP intelligent system stores entire order information in real-time that is extremely transparent easily traceable.

Sunfeng Fabric connects skin the Earth with Polycaprolactone filamentsystem that is clear low in carbon. Biodegradable and easy recycle. It virtually zero emission recycling 95% waste.