Email:[email protected]

Email:[email protected]

PLA fibers, or fibers made of polylactic acid, a type of synthetic material used to produce clothing and other textiles. These carbon fiber filament are plant-based, making them environmentally friendly. This article will explore the Beneficial Features of Polylactic Acid Fibers and the Impacts they are Making on Textile Engineering.

Polylactic acid fibers are made from plants, they are biodegradable and they also require less energy to produce than regular synthetic fibers. That means they put less pollution and greenhouse gases into the air.

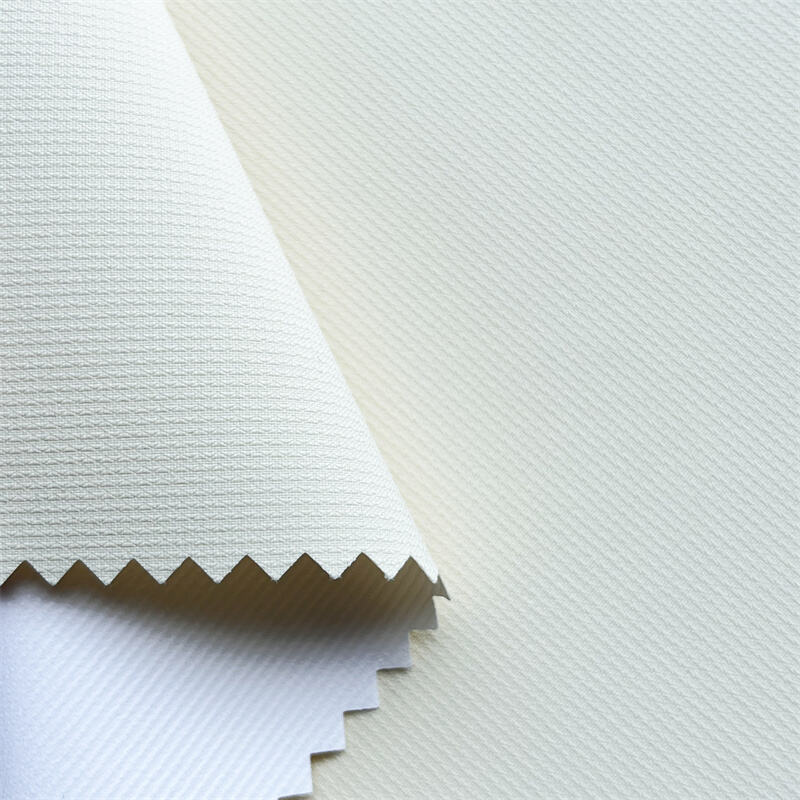

To make polylactic acid fibers, you begin with sugar derived from plants such as corn or sugar cane. Next, the sugar is converted to lactic acid, a key building block for PLA. The Outdoor water resistant fabric is then converted into fibers that can be woven into fabrics for garments, furnishings and other products.

Because they are made with polylactic acid fibers, we are making it better in a way that is friendlier for the Earth than making synthetic fibers with oil. We can create a sustainable footwear industry by utilizing plants. Sunfeng is a company that works with these fibers to reduce environmental impact.

There is a wide variety of applications for polylactic acid fibers. They learn softer and comfort fabrics can be incorporated into a mixture with materials like polyester or cotton. PLA fibers are now being used by many clothing brands to produce comfortable and stylish clothing for eco-conscious consumers.

In addition to textiles and clothing for human consumption, these water repellent fabric can be used for furniture, non-woven fabrics (for example, in diapers) and medical products. They are versatile and can be cooked in various ways. Sunfeng is working on ways to utilise these fibers to provide quality, sustainable textiles.

Polylactic Acid fibers are the key to transforming the textile industry with a more sustainable solution than commonly-used synthetic fibers. They are biodegradable, created from renewable plants, and require less energy to manufacture.” They are ideal for fabric products including clothing. Brands such as Sunfeng are being used to meet the growing demand for eco-friendly items.

company is accredited by GRS, Bluesign, Okeo-tex 100, the Okeotex Step, Higg Index as well as BSCI. company also maintains extremely strict quality control. From testing samples to dyeing and finishing all processes are monitored and Polylactic acid fibersand. ERP intelligent system keeps every order's data in real-time is fully transparent.

Sunfeng founded in 2005 is a company that high-tech and focuses on R D and production of breathable and sustainable functional fabrics. The company is equipped with the most recent R D laboratories and CNAS test labs. It also collaborates with academies and scientists to optimize technology manufacturing for various scenarios and market demands.

2022, the Company founded Sichuan Sunfeng Digital and Polylactic acid fibersTextile Co., Ltd combines textiles dyeing, finishing and weaving. In addition our Vietnam base has weaving facilities dyeing finishing facilities. weaving factory began operations in 2021, with an estimated capacity of up to 40 million meters per year.

Connecting skin to the Earth, each meter Sunfeng Fabric improves the sustainability performance of an eco-system is low in carbon and transparent. Polylactic acid fibersis easily recyclable or biodegradable.Nearly zero-emission production recycling 95% of the waste.